Verifying the commitment to pellet loss prevention and the Operation Clean Sweep Programme:

The OCS Europe Certification Scheme

In 2020, Plastics Europe, the association representing plastics manufacturers in Europe and EuPC, the association of European Plastics Converters, committed to jointly develop an OCS Europe certification scheme aimed at controlling and documenting compliance with requirements targeting minimization of pellet loss across the entire plastic supply chain. The requirements of this scheme are developed on the basis of the six pillars of Operation Clean Sweep. It will also support the effective, harmonised and quantifiable implementation of the Operation Clean Sweep programme. The certification scheme has been developed together in consultation with Industry experts, trade associations, NGOs, policy makers and certification bodies. In May 2022, a public consultation was conducted to gather feedback from various stakeholders. Plastics Europe and EuPC will target the maximum coverage of the certification within their membership.

The OCS Europe certification scheme is aimed at controlling and documenting the compliance of companies throughout the entire plastics supply chain with requirements on the prevention of plastic pellets, powders and flakes loss to the environment.

The two principal documents of the certification scheme are:

Rules and Principles: The Rules and Principles document summarises the founding principles of the OCS Europe Certification Scheme and contains other practical information such as auditor requirments, how to be certified etc.

Download the Rules and Principles document:

- English (version 2.0)

- French (old version - translation to be updated)

- Dutch (old version - translation to be updated)

- German (old version - translation to be updated)

- Italian (old version - translation to be updated)

- Polish (old version - translation to be updated)

Requirements: The OCS Europe Certification Requirements document consists of the set of requirements to comply with in order to be OCS Europe certified. The requirements of this scheme are developed on the basis of the six pillars of OCS.

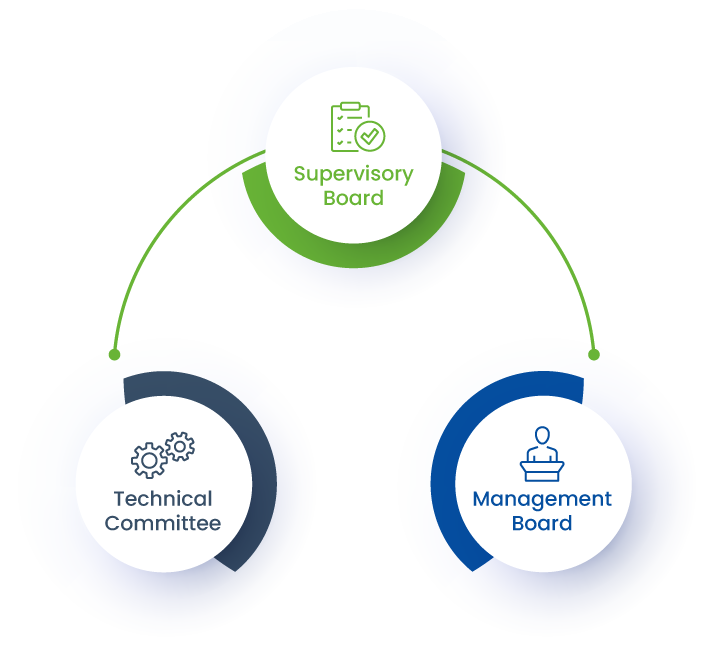

Scheme development and operation

The scheme development is organised in three years audit cycles. Requirements are reviewed for each audit cycle in a process involving the Technical Committee, Management Board and Supervisory Board. This process is initiated at least 1 year before the end of a “current” audit cycle. In case changes to requirements would be deemed necessary in the course of an audit cycle for the adequate implementation of the scheme or its accreditation, such changes would be proposed by the Technical Committee and approved by the Supervisory Board. During the 1st audit cycle, a review will be carried out one year of implementation of the scheme.

Governance

Info on Committees:

SUPERVISORY BOARD

Composition: a multi-stakeholder group of representatives from industry, policymakers and certification bodies. Its balanced composition ensures that no party can block the decision making of the Board, while ensuring its independence.

Remits: The Supervisory Board takes decisions on critical aspects of the Scheme. This would consist in the approval criteria for new requirements, training, certification bodies and certification body accreditation and inclusion in the Scheme’s public register.

The Supervisory Board reviews feedback on the scheme implementation by auditors/certification bodies with a view of a consistent implementation and interpretation of the requirements. The Supervisory Board ensures the scheme implementation enables to reach an overall decrease of plastics pellet emissions through continuous improvement towards the goal of zero pellet losses. The Supervisory Board will ensure development of the scheme to reach across the supply chains in order to achieve loss reduction.

Decision making: Members of the Supervisory Board strive to make decisions by consensus. In case no consensus may be reached, decisions are made by a majority vote with a minimum of 2/3 votes with a quorum of 50%.

Minority positions shall be documented on request of and made public in the minutes of the Supervisory Board meeting.

MANAGEMENT BOARD

Composition: 2 voting representatives of each scheme owner (EuPC & Plastics Europe) + observers from the association representing transport/logistics sector and CEFIC (Safety & Quality Assessment for Sustainability scheme in short SQAS*) and other mutually recognized certification schemes

Remits: It makes proposals for new requirements and organization of the scheme, and is responsible for its day-to-day running. The board also administers funds allocated by Plastics Europe and EuPC.

Decision making: the Management Board will strive to reach consensus but in case of disagreement may decide by simple majority of its present or represented members provided a quorum of two-third of its members present or represented is reached.

(*) SQAS is a third-party assessment system of logistics service providers and distributors managed by Cefic since 1992. The assessments are carried out by a network of more than 60 independent European auditors and the assessment reports are uploaded into a database: https://sqas.org

TECHNICAL COMMITTEE

Composition: technical experts from the plastics value chain (producers, converters, transport/logistics/distribution). Additional members may be added upon review of their expertise by the Supervisory Board.

Remits:

- Develop the OCS Europe Core Requirements;

- Review the different OCS Europe Specific Requirements of each OCS Europe Certification Modules to ensure coherency;

- Participate in the testing of the software developed;

- Ensures a technical follow-up of the scheme to improve quality and consistency control, develop guidance/interpretation documents and when necessary, propose modifications to requirements (see Annex I)

- Will provide technical advice during the review of the scheme at the end of each “audit cycle”.

- The Technical Committee reports to the Management and Supervisory Board.

Decision making: Decisions are made by consensus. In the occurrence that the Technical Committee cannot reach consensus, they will escalate the issue to the Management and Supervisory Board as appropriate.

Certification bodies & Auditors Requirements

CERTIFICATION BODY

The certificate in accordance with the OCS Europe Requirements should be issued by an independent Certification Body with technical competence in the plastic sector, able to demonstrate it through an accreditation issued by an International Accreditation Forum (IAF) member accreditation body for product certification activities in accordance with ISO/IEC 17065 in the plastics sector and/or ISO/IEC 17021 for audit and certification of management systems in the plastics sectors (raw material producer/supplier, logistics/transport/cleaning, converters, recyclers…).

The certification bodies shall be contracted by the scheme owners.

It is the intention to have the scheme itself be accredited. For this purpose, when appropriate, an application will be made to European Accreditation https://european-accreditation.org.

General criteria for an OCS Europe Certification Auditor:

- Academic training: University / Bachelor degree of a technical nature (engineering, physics, chemistry or similar).

- Professional experience: Four years working for a Certification Body, of which at least two in functions related to the conformity assessment of environmental/quality management and/or of plastic products. The auditor can be an employee of the Certification Body or can work as independent auditor for the Certification Body

- Knowledge of conformity assessment techniques: Having passed a training course of auditors of environmental/quality management systems (EN ISO 14001 and/or EN ISO 9001).

- Knowledge of European/national/local regulation related to pellet loss

- Languages: the auditor must speak English + one of the national languages of the country where the audit is carried out.

- Experience in plastic value chain OCS evaluation*:

- Participating in at least two audits or inspections as observer in OCS Europe certification audits.

- Carrying out at least 1 audit in OCS Europe certification practices. This audit will be supervised by a person with the corresponding qualification, who will complete a supervision form in which will reflect if, in his/her discretion, the candidate has the necessary technical competence to carry out the visit alone.

- Attending a specific training course on the OCS certification carried out by an Operation Clean Sweep licensee entity and by the OCS Europe scheme responsible at the certification body.

*This requirement shall apply to the lead auditor or the auditor who intend to train future auditors.

CONTROL OF AUDITORS

It is the responsibility of certification bodies to control the performance of the activities carried out by their auditors.

CONTROL OF CERTIFICATION BODIES

It is the intention to have the OCS Europe scheme accredited as soon as possible so that the control of certification bodies may be done by an independent third party.

Before this accreditation may be obtained, it will be the Task of Scheme owners (PlasticsEurope and EuPC) to organize this control. During this interim period, such quality issues shall be brought to the attention of the Technical Committee and/or Management Board as appropriate and be reported to the Supervisory Board

After the accreditation of the scheme, certification bodies will be accredited by National Accreditation bodies

The first step is to ensure your facility is compliant with all the mandatory Requirements listed in the OCS Europe Certification Scheme Requirements. The Requirements are broadly divided into two categories which are developed on the basis of the 6 pillars of OCS:

- Core Requirements: Set of requirements essential to achieve OCS Europe Certification regardless of the supply chain position. This means that these set of requirements are applicable to any facility in the plastics value chain (Producers, Converters and Transporters). All Core requirements are mandatory requirements

- Specific Requirements: Specific Requirements are divided into three modules and each module consists of particular requirements depending on the facility’s supply chain position:

- Module 1: Production covering plastics manufacturers and integrated compounders;

- Module 2: Master-batching compounding and converting;

- Module 3: Transport and Logistics companies (still to be developed)

The next step is to request a third-party audit from one of the approved Certification Bodies (CB). You can find the list of approved OCS Certification bodies here.

The Certification Body will provide an application form to the facility and will thereafter organise and prepare for the audit. An auditor will be assigned and will visit the facility to audit against the OCS Europe Certification Requirements. The audit will have documentary evaluation as well as evaluation of the measures and procedures implemented to combat pellet loss for example, retention grids across the physical boundary of the facility.

Please note that the OCS Europe audit is at facility level and in order for all the pellet handling facilities of your company to be compliant with OCS Europe Certification Scheme, each facility will need to demonstrate its compliance via the third party OCS Europe audit.

The pass/fail checklist is uploaded digitally to the OCS Europe Intranet of the CB which grants the passing of the audit, and the certificate is awarded by the respective CB.

In case of non-conformity(ies), a corrective action or action plan should be sent for documentary evaluation within 30-days, upon which the facility may be granted an audit certificate

Once the facility is awarded the OCS Europe certificate, the name and location of the OCS Europe certified facility for which the certification is awarded becomes then available on the OCS Europe public register of certified companies.

Control audits: The validity of this certificate will be 3 years with an annual control audit (documentary not physical) carried out during the first two years of validity of the certificate and a renewal audit before the expiration of the certificate in the third year.

The control audits will be carried out in order to verify that the conditions that gave rise to the initial granting of said certificate are maintained and to ensure continuous improvement, through the correct implementation of the action plan proposed by the organization.

In the case of detecting non-conformities, the facility will have a period of 30 days to provide a corrective action plan, for which it must send a corrective action plan to the certification body, which will proceed to study and evaluate them. The certification body shall review the implementation progress of the corrective action plans in the control audit.

Renewal audit: The certification body will carry out a renewal audit every three years, in order to check whether the conditions that gave rise to the initial granting of said OCS Europe certificate are maintained.

Removal from registry: When a site/company fails a control or renewal audit and does not provide evidence of implementation of corrective action in due time, it will be removed from the public registry within two months of the notification of the failed audit. The facility should re-apply for the certification.